Verband Europäischer Straßenfräsunternehmungen e.V.

Association of European Road Milling Enterprises

Levelling

When milling off asphalt or concrete pavements, milling depth control units fitted to the machines help to precisely remove the pavement at the desired slope or at a specific depth. A basic distinction is made between copy milling and levelling.

Copy milling

When copy milling, the existing pavement surface serves as a reference, that is, the layout of the layer to be milled is copied, and the layer is removed at the specified depth.

Levelling

|

When levelling, the layout of the pavement can be changed in accordance with

specifications. A variety of systems can be used for this application,

depending upon the purpose of the construction project and the conditions on the

job site:

|

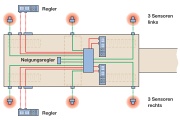

Multiplex system

Multiplex systemNumerous sensors are used to scan the reference plane on both sides of the machine. A control unit then determines the mean value from the measured values and regulates the milling depth accordingly, in this way compensating longitudinal irregularities. |

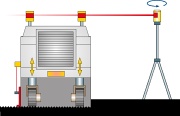

Levelling surfaces with the laser sensor

Levelling surfaces with the laser sensorA transmitter pre-determines the reference plane using a rotating laser beam. The control unit then regulates the milling depth by means of two receivers on the machine. This method is perfect for creating new, level surfaces at a high precision. |

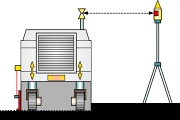

Levelling by means of 3D

Levelling by means of 3DThe 3D system measures the absolute position of the machine, compares it to previously entered target values and then automatically regulates the height and/or inclination of the machine. By using this method, complete newly designed surfaces can be milled without the need of a stringline. At the same time this method achieves an especially high degree of precision. |